- Need assistance?

- 1-888-762-2568

- Contact Us

Accelerating Innovation for Life Sciences

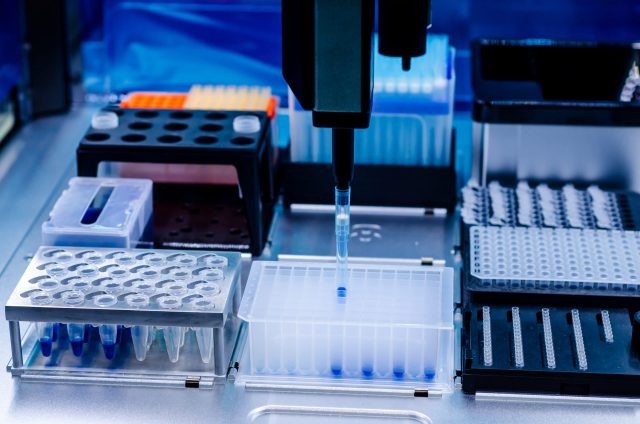

Complete Solution for Biosamples, Sample Preparation & Analysis

Product Categories

From high-quality biospecimens and reference standards to kits, reagents, and automated instruments, you’ll find products that are optimized to accelerate your innovation.

Custom Services

Whether you need a reliable source of high-quality components for manufacturing or CLIA lab testing needs, or are looking for custom biospecimen sourcing, extraction, and analysis services, BioChain is ready to deliver.

Spatial Multiomics

Fully customizable, end-to-end process offering 10X Visium & NanoString GeoMx DSP services.

Biospecimen Procurement

Obtain even difficult-to-find biospecimens from a broad range of donors and indications with our global reach.

Custom Extraction & Purification

Put our standardized processes and extraction/purification expertise to work for your project.

Targeted Gene Profiling

Maximize insight and productivity by combining your biospecimen order with targeted gene expression analysis.

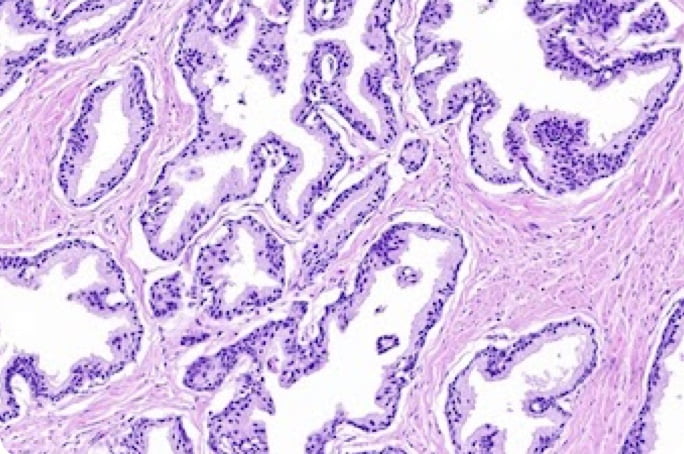

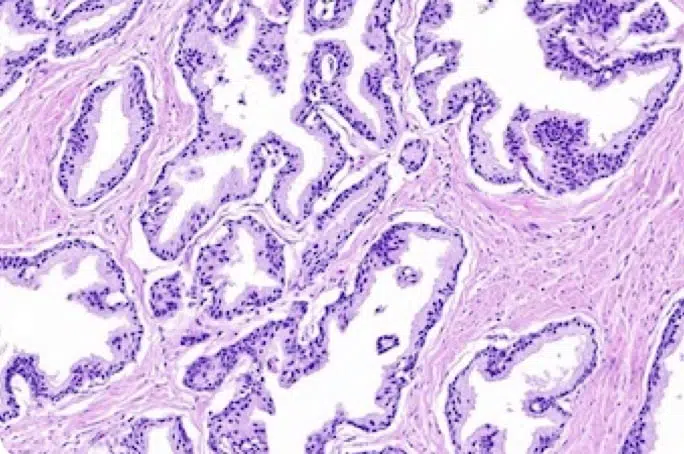

Histology Services

Save time and learn more by adding histological analysis to your catalog or custom biospecimen order.

OEM Manufacturing

Confidently source bulk DNA, RNA, protein, and more for your own manufacturing needs—ISO 9001:2015 certified.

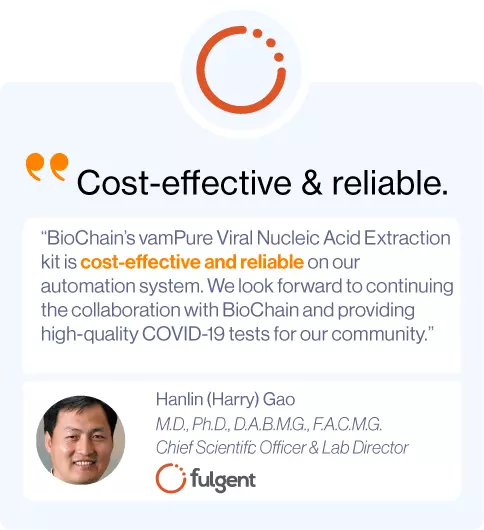

Trusted by Industry and Academic Leaders

Trusted by the top 500 global pharmaceutical, biotechnology and academic leaders for over 25 years, BioChain's biggest advocates are our customers.

Our goal is to advance accurate disease diagnosis and drug discovery by providing biomedical professionals with high quality biospecimens and optimized kits, reagents, and instruments.

Our Customers

Featured Posts

Publications

The high quality and global reach of our products and services can be seen in the large number of studies they are used in.

Upcoming Events

Need assistance? Get in Touch

Our experienced team is ready to help with technical support, sales support, custom services inquiries, and more.